Sensor

Interface Conditioners (SICs) For Distributed Intelligent

Sensor Systems (DISSs)

Many

industrial sensors are realized using Wheatstone Bridges; in

these cases, the sensors, being variable resistors, have

their signals reflected as small differential voltages with

maximum output voltages in the range of 25-50mV. The

function of a Sensor Interface Conditioner

(SIC) is to amplify and condition these signals so they

can be communicated to an output device; often this means

a computer that might be a significant distance from the

sensor (possibly in a different geographic location). The

SIC is usually close to the sensor, and traditionally the

communication to the output device would be done using the

industry standard 4-20mA 2-wire interface. Only recently,

are SIC's becoming available where the communication to

the output device is done using digital signals

and a serial interface. Granite SemiCom Inc. (GSC) has

developed a SIC with specifications close to the best in

the industry, where the digital signals are

transmitted to a

small computer board using an I2C digital serial link. GSC has also developed a Demonstration

System based on

Distributed Intelligent Sensor Systems (DISS's) that teaches how to use the SIC's and to

verify their excellent specifications, that

can be used to

program the SIC's using either a Graphical User Interface

(GUI) or a script from a file (or both), and that can

also be used to remotely control

and debug DISS's

from locations almost

anywhere on earth;

as long as an Internet

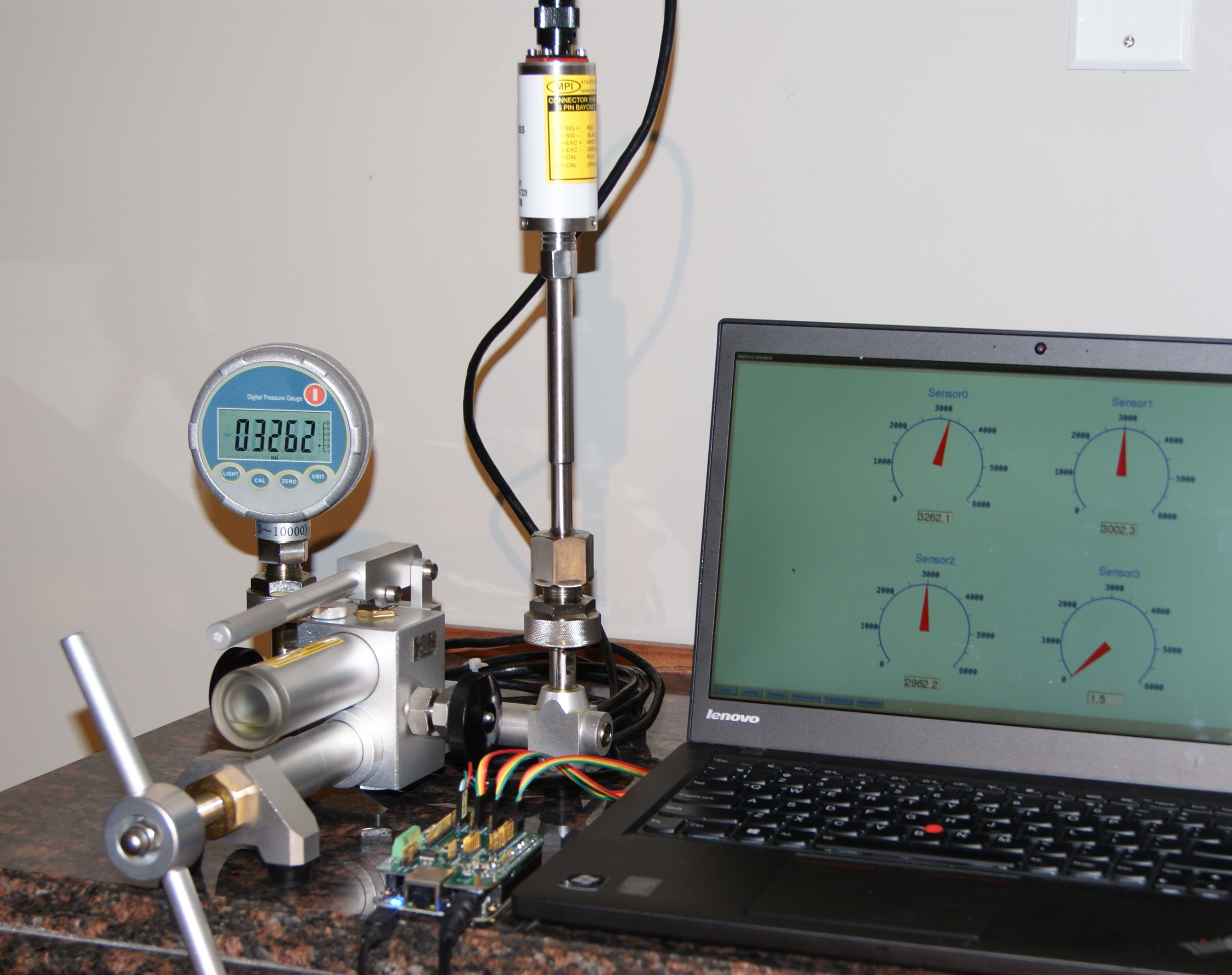

link exists. Shown is a high-pressure sensor that contains

GSC's SIC and communicates the the shown small-board

computer, which then communicates to the host computer

over a USB cable; CAT-5 and WiFi connections to the host

are also supported.

Sensor Interface Conditioner

Shown

is GSC's

SIC being evaluated for use as the interface to an

Industrial High-Pressure Sensor produced by MorHEAT Inc. (www.morheat.com)

for “Melt

Pressure”

applications;

GSC''s SIC is inside the sensor housing and connected to a

smart computer board using the I2C

interface; the

demonstration software all runs on the computer board but the higher levels can run

on remote host computers.

In the Demonstration

System, with all the GUI software running on the small

computer board, the

output of the software is communicated to a host computer

using a secure encrypted link based on the SSH

protocol with the -X option specified (that allows remote

X-windows viewing). In this picture, the SSH connection to

the host computer is through a USB cable; alternatives

that have been developed are through 100Mbs Ethernet

cables or wirelessly using WiFi. Any

controller or smart computer board that supports I2C can

be connected to GSC's SIC; for

the Demonstration System,

the controller is based on using the Beaglebone Black

computer with a Controller Interface

Board (CIB) also

developed by GSC and supplied with its Demonstration

System. The CIB allows for 4 SIC's to be

interfaced with a single board; it also has an 8-bit GPIO

parallel interface, temperature sensor, programmable power

supply, and supply voltage and

temperature measurement

feedback for robust operation and remote

debugging.

Shown

is GSC's

SIC being evaluated for use as the interface to an

Industrial High-Pressure Sensor produced by MorHEAT Inc. (www.morheat.com)

for “Melt

Pressure”

applications;

GSC''s SIC is inside the sensor housing and connected to a

smart computer board using the I2C

interface; the

demonstration software all runs on the computer board but the higher levels can run

on remote host computers.

In the Demonstration

System, with all the GUI software running on the small

computer board, the

output of the software is communicated to a host computer

using a secure encrypted link based on the SSH

protocol with the -X option specified (that allows remote

X-windows viewing). In this picture, the SSH connection to

the host computer is through a USB cable; alternatives

that have been developed are through 100Mbs Ethernet

cables or wirelessly using WiFi. Any

controller or smart computer board that supports I2C can

be connected to GSC's SIC; for

the Demonstration System,

the controller is based on using the Beaglebone Black

computer with a Controller Interface

Board (CIB) also

developed by GSC and supplied with its Demonstration

System. The CIB allows for 4 SIC's to be

interfaced with a single board; it also has an 8-bit GPIO

parallel interface, temperature sensor, programmable power

supply, and supply voltage and

temperature measurement

feedback for robust operation and remote

debugging.

Tthe GIC Sensor Interface Conditioner (SIC) is very high-accuracy, highly reconfigurable, and includes self-debug capability allowing for remote debugging in the event of failure.

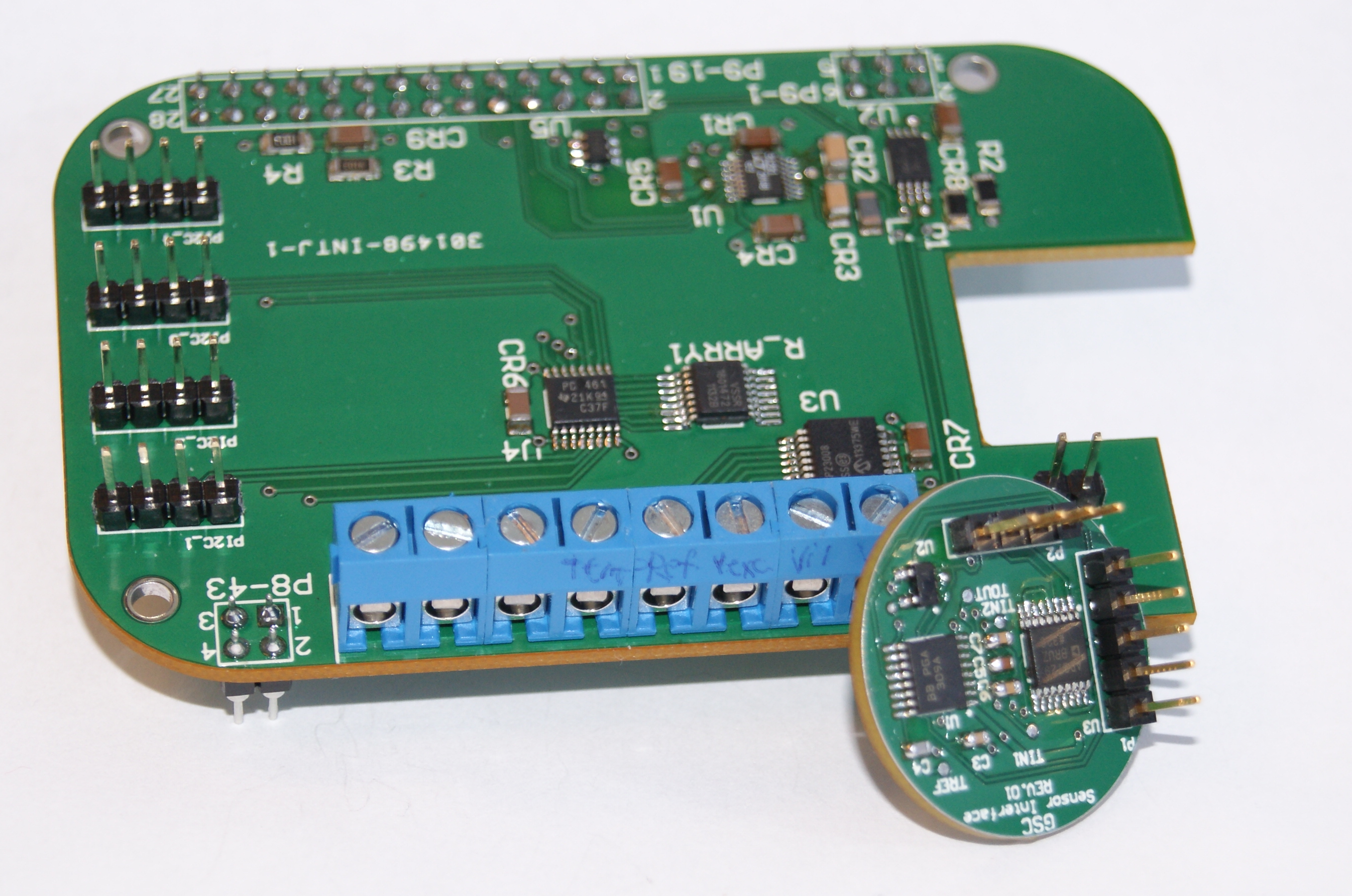

Controller Interface Board

A Sensor Controller Interface Board (CIB) has also been developed, and is supplied as part of GSC's Demonstration System. The Demonstration System helps teach how to program the SIC's, and to demonstrate their functionality and accuracy. GIC's Controller Interface Board (often called a “Cape” ) connects to the Beaglebone Black (BBB) computer board available from Sparkfun (www.sparkfun.com) and other distributors. The BBB is relatively fast, has lots of memory, both RAM and non-volatile (a 4Gbyte eMMMC), enables connecting to the Internet for remote control and communication straight-forward, and with its Debian operating system, provides a wealth of open-source software that greatly minimizes development time. For example, secure encrypted communication to the Internet using SSH is used. However, using the BBB is just one alternative; the SIC's can alternatively be connected to any controller that has an I2C interface, and GSC with its Design Services Model readily supports program development for connecting to alternative controllers. GSC's Demonstration System includes a pre-programmed BBB and Cape Interface Board to simplify users getting started; the Demonstration System also includes 4 SIC's, and a Sensor Emulator Board including a pressure sensor.

The Controller Interface Board (CIB) allows four SIC's to be connected to the CIB and used at the same time, even when they have identical Device addresses. Indeed, each of the four I2C channels can also be connected to multiple Devices, but all Devices on a single channel must have unique addresses. The number of channels can be expanded on custom boards in response to a customer's request.

The CIB has a programmable

power supply voltage, has an 8 pin GPIO, and has output

voltage verification and CIB temperature verification to

support remote verification of

correct functionality.

Alternative connections for the BBB controllers are

through USB cables, or wirelessly using either a WiFi

dongle or a Bluetooth dongle plugged into the BBB's USB

port. The GSC Demonstration System comes with software

that is all running

on the BBB itself to simplify getting started. In a

non-demonstration system, the top-level software would run

on the host computer (this is currently supported for some

operating systems), while the driver-level software

would run on the small-board

controller. In

this case, the required bit rate for communicating to the

controller is very low, in the range of

kbs. In the GSC Demonstration System, with all interface

software running on the BBB controllers, the host operates

just as an X-Windows display, and communications between the host and

the BBB controllers is done using the SSH

(Secure Shell) protocol

with the -X

option. This supports hosts with any operating system, and

is also highly secure with all communications to the BBB controllers

encrypted for

security. The down-side of running all software on the

BBB controllers is

higher data rate

connections to the controllers are needed (but these are still

modest data rates), and the controllers

need to have more capabilities (which the BBB controllers

do have). In applications where less powerful controllers

are used, the top level software would always run on the

host computer.

The CIB has a programmable

power supply voltage, has an 8 pin GPIO, and has output

voltage verification and CIB temperature verification to

support remote verification of

correct functionality.

Alternative connections for the BBB controllers are

through USB cables, or wirelessly using either a WiFi

dongle or a Bluetooth dongle plugged into the BBB's USB

port. The GSC Demonstration System comes with software

that is all running

on the BBB itself to simplify getting started. In a

non-demonstration system, the top-level software would run

on the host computer (this is currently supported for some

operating systems), while the driver-level software

would run on the small-board

controller. In

this case, the required bit rate for communicating to the

controller is very low, in the range of

kbs. In the GSC Demonstration System, with all interface

software running on the BBB controllers, the host operates

just as an X-Windows display, and communications between the host and

the BBB controllers is done using the SSH

(Secure Shell) protocol

with the -X

option. This supports hosts with any operating system, and

is also highly secure with all communications to the BBB controllers

encrypted for

security. The down-side of running all software on the

BBB controllers is

higher data rate

connections to the controllers are needed (but these are still

modest data rates), and the controllers

need to have more capabilities (which the BBB controllers

do have). In applications where less powerful controllers

are used, the top level software would always run on the

host computer.

Graphical User Interfaces

The software interface to the

SIC's supports interfacing using either Graphical User

Interfaces (GUI's), using a script programming interface

where the programs are previously stored in files, or

optionally using both approaches. Detailed help on the

software interfaces is included in the extensive help files

of the GUI's supplied with the Demonstration System.

The software interface to the

SIC's supports interfacing using either Graphical User

Interfaces (GUI's), using a script programming interface

where the programs are previously stored in files, or

optionally using both approaches. Detailed help on the

software interfaces is included in the extensive help files

of the GUI's supplied with the Demonstration System.

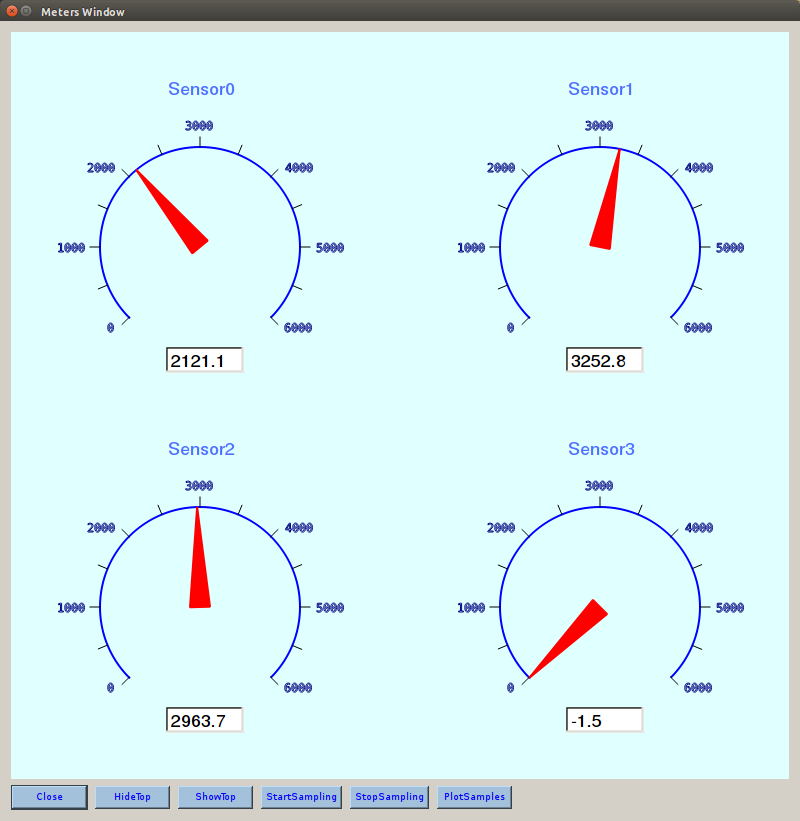

The

software approach recommended by GSC is to separate the

details into three different Abstraction Levels: the User

Level, the Programming Level, and the Driver Level. For the

GSC Demonstration System, the User Level is a GUI showing 4

meters and digital readouts, one for each of the 4 sensors

attached to the CIB (Cape Interface Board). The User GUI has

buttons to start and stop sampling, to plot the results of

sampling, and to display

(or hide) the GUIs for lower levels of abstraction, namely

the Programming GUI (PGUI),

and Device Register

Interface GUI (DGUI).

The PGUI is displayed and changed when it is desired to

program the SIC's differently than their default values. The DGUI is only displayed,

and possibly changed, when the sensor interfaces are being

debugged. Both of these top level GUI's can be run

remotely assuming an Internet communication channel.

Availability

The Sensor Interface Conditioners (SICs) are available in minimum quantities of 10. The Demonstration Platform consisting of a pre-programmed Beagleboard Black computer board, a GSC Controller Interface Board (CIB), 4 SICs, and a Sensor Emulator Board is available in minimum quantities of 1. Please contact GSC for pricing information in both cases.

Sensor Interface White Paper

The SIC and CIB developed by GSC are described in more detail along with specifications in a White Paper.

© 2015 GSC